Iron ore pellet dryer is also called refined iron ore dryer. It is specially designed for drying iron ore pellet, iron powder, iron scrap, copper ore concentrates and refined iron ore. Taeda iron ore pellet dryer can realize drying and oil removing into one body. It is featured in small footprint, stable performance and low energy consumption.

The Iron ore pellets dryer is made into rotary body, lifting blade, driving device, and supporting device.It has advantages of reasonable structure, high efficiency, low energy consumptionand convenient for transportation.

Working principle:

Dryer drum is a slightly inclined cyclinder. Wet materials enter dryer from higher end and dried products are collected from the other end. Hot air can enter iron ore pellet dryer either from feeding or discharging end. There is lifting plates installed in drum and these lifting plates will scatter raw materials repeatedly during drum rotating process so that material can fully contact with hot air and improve drying efficiency. Heat source matched with dryer can be hot air and hot flue gas. Specific option of heat source can be chosen based on material property and quality requirement.

Taeda Iron ore pellets dryer holds strong overload resistance and large processing capacity. By adopting combined drying mode, Taeda Iron ore pellets dryer consumes less energy and cost less investment. High temperature exhaust gas can be recycled and thermal loss is less.

Running parameters of Taeda Iron ore pellets dryer can be adjusted ba

Taeda Iron ore pellets dryer is featured in simple operation, stable running performance, good seal effect and convenient seal performance. It is a ideal drying equipment. Rational structure and perfect workmanship makes Taeda Iron ore pellets dryer durable.

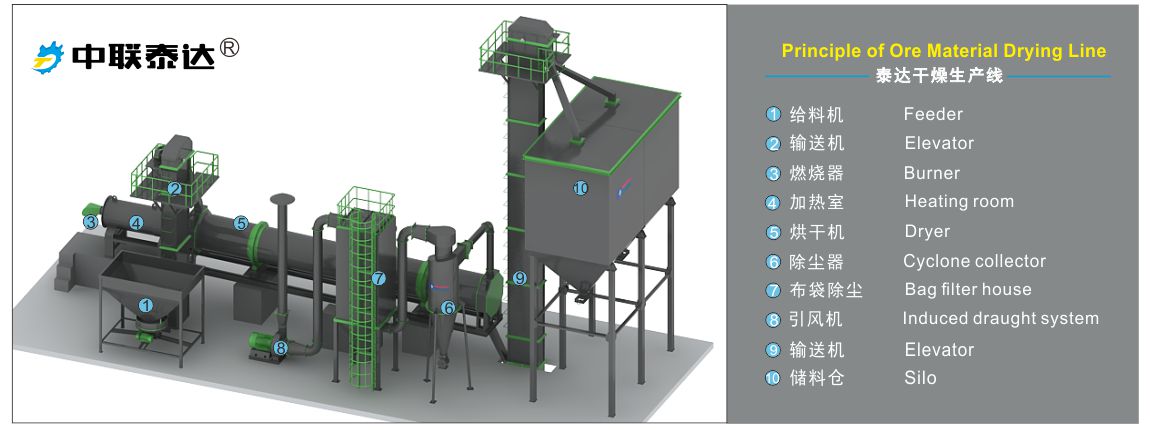

Whole drying system holds flexible configuration. We can configure feeder, heat source, conveying, dust collecting, product conveying and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |