Fluorite ore dryer or fluorite drying machine is also a kind of rotary dryer, it is mainly composed of rotary cylinder, high-speed scattered equipment, cleaning device, transmission device, transmission equipment, hot air equipment, deceleration machine, supporting devices, sealing device, etc.

Fluorite ore dryer is with reasonable design, perfect workmanship, stable running, advanced technology, high output, low energy consumption, high mechanization degree and so on. Slag, river sand, limestone, clay, quartz sand, grain slag, slurry and sludge can be dried by the fluorite dryer.

In production and processing of fluorite ore, fluorite ore dryer is very important working procedure. Fluorite ore dryer has the advantages of of large treating amount, low unit energy consumption, good drying effect.

Fluorite ore dryer is dedicated drying equipment that can dry all kinds of ores and rocks, such as iron ore, copper ore, iron ore pellets, iron ore concentrate, fluorite ore, phosphate ore, molybdenum ore, rare earth ore, quartz, limestone, raw iron fillings, iron oxide, etc.

Taeda fluorite powder dryer is specially designed for fluorite powder drying. We fully take features of fluorite powder into consideration druing designing. Reasonble structure of Taeda fluorite powder dryer can dry fluorite powder material with 25% moisture to lower than 4% one time. It is featured in large capacity, low energy consumption and low cost.

Taeda fluorite powder dryer adopts automatic centralized control mode which makes it run continuously. Fluorite powder materials fully scatter in dryer drum and contact with hot air which makes sure good drying effect and strong drying ability. Drying task can be finished in short time and whole drying process is done in a smooth procedure. Superior manufacturing texture of Taeda fluorite powder dryer guarantees longer service life and low malfunction rate.

Taeda fluorite powder dryer is characterized by wide application range, high production capacity, strong evapration ability, simple structure, small footprint and low investment/running/maintenance cost. Heat source system can match with coal gasifier, coal hot air furnace, pellet burner, diesel burner and natural gas burner to produce proper hot air.

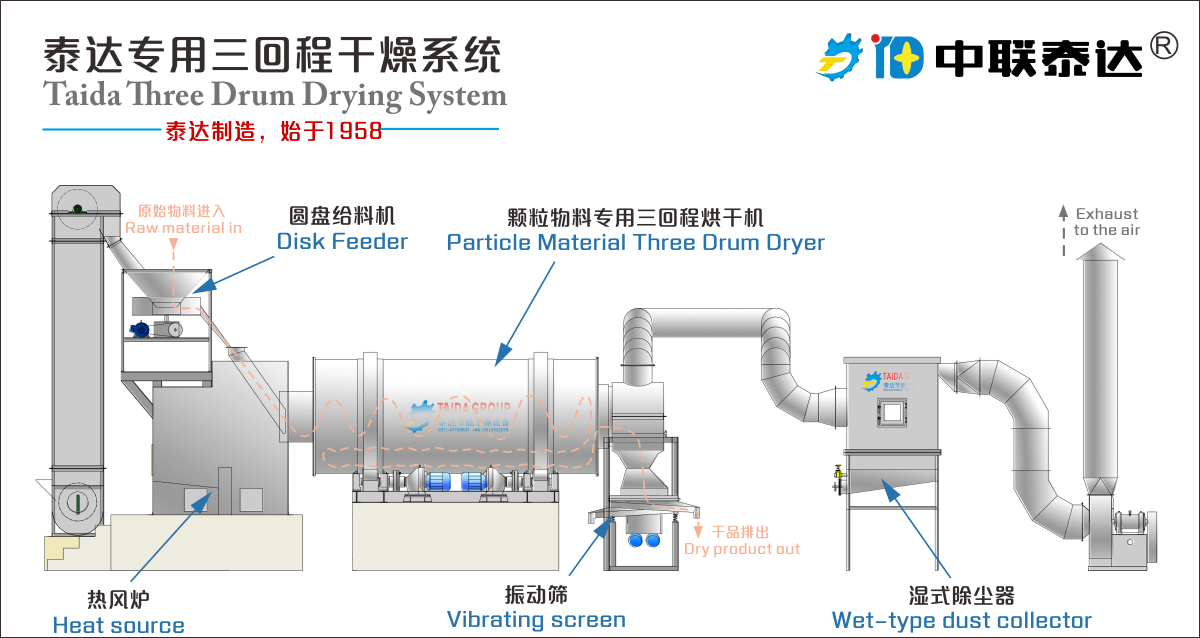

Whole drying system holds flexible configuration. We can configure feeder, heat source, conveying, dust collecting, product discharging and packing unit based on customers' requirements. Taeda diamond stone dryer can be applied for various industries and various customers so that to make sure each customer can find suitable drying equipment from Taeda.

|

Item |

Capacity (t/h) | Power (Kw) | |||

| Slag | Fly Ash | Clay | Sand | ||

| TDLT320.1 | 5~10 | 4 | 4~6 | 10~15 | 11 |

| TDLT320.2 | 10~15 | 6 | 6~8 | 15~20 | 11 |

| TDLT325.1 | 20~25 | 8 | 8~12 | 20~25 | 15 |

| TDLT325.2 | 25~30 | 10 | 12~15 | 25~30 | 15 |

| TDLT328 | 30~35 | 15 | 15~20 | 35~40 | 22 |

| TDLT330.1 | 35~40 | 20 | 20~25 | 40~45 | 30 |

| TDLT330.2 | 40~45 | 25 | 25~30 | 45~50 | 30 |

| TDLT332.1 | 45~50 | 30 | 30~35 | 50~60 | 44 |

| TDLT332.2 | 50~60 | 35~40 | 35~40 | 60~70 | 44 |

| TDLT336 | 60~70 | 40~45 | 40~45 | 70~80 | 60 |

| TDLT338 | 70~80 | 45~50 | 45~50 | 80~90 | 60 |

| TDLT340 | 80~90 | 50~60 | 50~60 | 90~100 | 74 |