【Production capacity】:

【Feeding moisture】:15% to 55%

【Feeding size】:0.1 to 100mm, powder, filter cake or flake type material.

【Applicable material】:Feldspar, potash feldspar, soda feldspar, nepheline, calcium hydroxide, slaked lime, powder, zirconia, aluminium hydroxide and filter cake calcium mineral material.

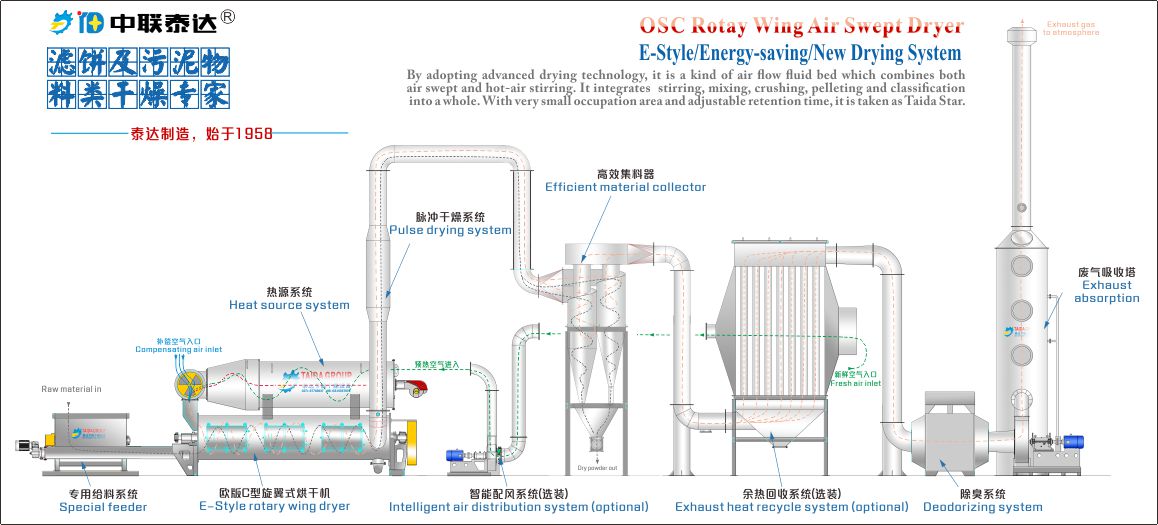

Stone Powder/Filter Cake Air Swept Dryer is a kind of drying system specially designed for super fine micro powder and filter cake materials after wet grinding process. Feeding moisture ranges from 15% to 55%. Moisture of final product from micro powder filter cake air swept dryer can be reduced to lower than 1% one time. Typical raw materials contain feldspar, potash feldspar, soda feldspar, nepheline, calcium hydroxide, slaked lime, powder, zirconia, aluminium hydroxide and filter cake calcium mineral material. Materials are forced to flow out of dryer along with airflow. High speed air swept dispersing blade will form vortex which will improve drying effect. Micro powder fliter cake air swept dryer is featured in low emission, less energy consumption, less pollution and low running cost. Compared with traditional micro powder drying equipment, Taeda air swept dryer can effectively save cost and holds better drying effect. Owing to great profit it can bring, Taeda micro powder filter cake air swept dryer enjoys great popularity among different customers.

Wet materials (super fine powder or filtered cake after pressing) are continuously sent to air swept dryer. In first-level drying chamber, materials will enter vortex generator with hot air and form boiling state airflow. Materials are dispersed, dehydrated and dried. Following, materials enter second drying chamber where moisture is furthur evaporated according to curve. After that, materials will enter third drying chamber for slow-speed drying. Air swept blades set inside dryer drum will lift and stir raw materials and make materials mix with airflow. The contact surface between materials and airflow is enlarged so that improve drying speed and drying uniformity. Final dried products hold stable moisture. Final moisture can be reduced to lower than 1% one time. At present, micro powder filter cake air swept dryer has been widely applied in Hunan, Henan, Shanxi and many oversea projects. Customers are satisfied with final product quality and drying effect.

New Design Guarantees Small Footprint And Good Drying Effect

Micro powder filter cake air swept dryer is Taeda fifth generation drying system which holds good drying effect for feldspar, potash feldspar, soda feldspar, nepheline, calcium hydroxide, slaked lime, powder, zirconia, aluminium hydroxide and filter cake calcium mineral material. Its occupation area is only one third of common dryer. As a kind of continuous drying system, it holds great drying effect.

Scientific Structure And Easy Operation

There is vortex generator, air damper, blocking ring, stirring blade and crushing hammer set on high speed rotary wing shaft. With scientific design, raw materials move smoothly in dryer. Wall sticking problem can be effectively avoided. Meanwhile, wet micro powder and filter cake can be evenly dried into dry powder so that to improve drying efficiency.

Low Energy Consumption and Cheap Running Cost

Materials present boiling status inside air swept dryer under the function of vortex. Materials can fully contact with hot air and moisture can be evaporated fast. Both energy consumption and running cost are low. Customers can recover investment cost for drying equipment soon.

More Flexible Configuration and Low Exhaust Emission

Whole drying system holds flexible configuration. We can configure hopper, feeder, heat source, conveying, dust collecting, product conveying and water scrubbing device. Professional team provides one-step service amd customizes suitable equipment ba

|

Model

|

TDOSC310 | TDOSC510 | TDOSC1010 | TDOSC2010 | TDOSC3010 | TDOSC4010 | TDOSC5010 |

| Thermal power (kCal/h) | 100,000 | 150,000 | 300,000 | 650,000 | 1,300,000 | 1,800,000 | 2,500,000 |

| Hot air volume (m3/h) | 2500 | 3720 | 7500 | 16000 | 32000 | 45000 | 70000 |

| Evaporation capacity (kg/h) | 360 | 550 | 1100 | 2200 | 4500 | 5500 | 7800 |

| Motor power(kW) | 7.5 | 11 | 30 | 55 | 75 | 110 | 160 |

| Length (mm) | 3800 | 4080 | 5200 | 5500 | 6500 | 10500 | 12000 |

| Width (mm) | 1200 | 1500 | 2200 | 2900 | 3200 | 3800 | 4580 |

| Height (mm) | 835 | 1000 | 1390 | 1800 | 2200 | 2680 | 3320 |