【Fuel】: Coal, non-caked and weak bonding bitumite and anthracite

【Fuel consumption】: 800-3500kg/h

【Coal gas output】: 2,500-11,000 Nm3/hour

【Application range】: Widely used as furnace kiln of machinery, metallurgy, chemical industry, glass, building materials, light industry, drying, refractory materials and fertilizer

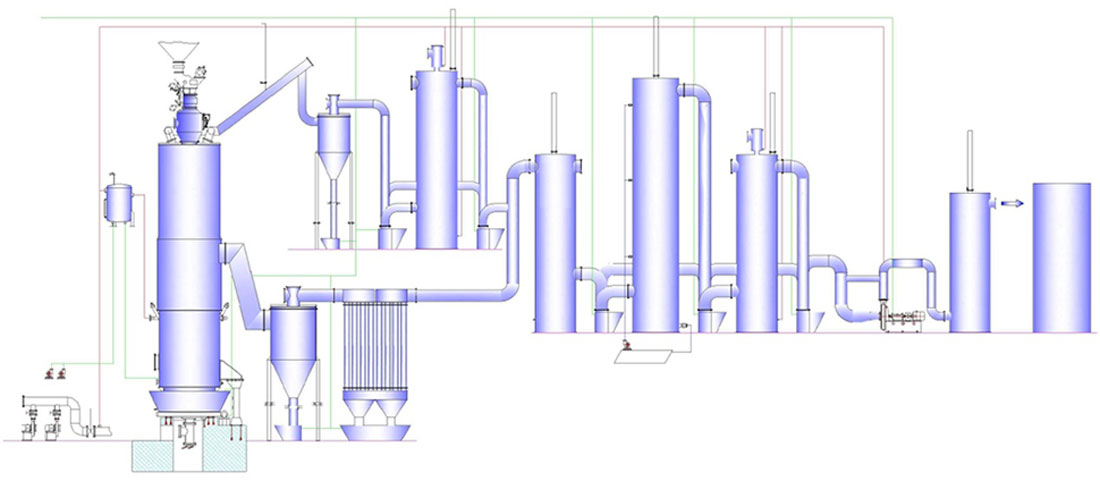

Coal gasifier is divided into two kinds, single-stage and double-stage by Taeda. Double-stage coal gasifier can also be called two-stage coal gasifier. Furnace body of double-stage coal gasifier can be divided into two parts, upper part and lower part. Raw materials are sent to upper part of coal gasifier by bucket elevator and the materials are distilled. Then, semi-coke is formed. The whole process for coal gas production is finished in coal gasifier. Coal gasifier is specially designed for gasifying bitumite. It has many advantages of high thermal value, environmental protection, large amount of by-product tar and good quality of jar. The coal gasifier developed by Taeda is characterized by good heat transfer effect, complete distillation, easy structure and convenient maintenance.

Advantages of Taeda Double-stage Coal Gasifier

1. Less pollution: coal gas at lower section is got from coke after pneumatolysis and distillation. There is almost no jar contained in coal gas, which makes coal gas at lower sections of coal gasifier cooled down after extreme cold. Large amount of sewage caused by direct contact between water and coal gas is avoided. Then, sewage discharge will be avoided and no pollution is caused to environment. Because quench water system is deficient in water, there is no sewage discharged out. Water recycling use can be improved by settlement treatment. It is easy to dispose.

2. Gasification intensity and comprehensive efficiency are higher than single-stage coal gasifier; can adapt to various coals, especially bitumite. Closed circuit is adopted for coal production in coal gas station. No sewage and air pollution is caused to environment. It saves a lot of water resources. With advantage of environmental protection, it holds much less running cost.

3. Owing to a distillation section added in double-stage coal gasifier, coal is heated gradually in distillation part and distilled with low temperature. All tar produced will not be decomposed. The stickiness of tar is low and with good fluidity.

4. Tar produced in upper coal gasifier is mainly light tar; less dust brought out; coal gas is purified by electric light and electric catching focal treatment.

5. Coal Gasifier is designed to be high production capacity, high gasification efficiency and better adaptability to various coals, high gas calorific value, and only need two worker to operate it, our coal gasifier can cope with different type heating furnace, kiln, steam boiler and ect.

Introduction To Each Component Of Taeda Double-stage Coal Gasifier

Coal adding section: coal position detector is installed in this section; automatic coal adding is realized by cooperation of coal position detector and stoker; full stock operation is guaranteed;

Distillation section: liner in furnace; this structure is designed after precise heat transfer and heat exchange calculation. Heat transfer efficiency is improved, which makes coal used for gasifier dried and distilled fully and effectively. Then, volatile fraction is separated out, which will improve the thermal value of coal gas and benefit the gasifying of coal gas at lower section.

Gasification stage: adopt water jacket structure; steam produced by itself for gasification at furnace bottom;

Coal feeding mechanism: Adopt advanced upper cylinder to add coal mechanism under bell cover; easy operation; simple maintenance; good air tightnes.

Ash cleaning mechanism: adopt ratchet pawl and hydraulic drive to remove ash at two sides; big ash knife is designed with self-designed plough ash removing knife; reliable and stable transmission; smooth ash removal; plough ash removing knife developed by our company has been applied to many gasifiers at home and abroad. It enjoys good reputations among its users.

| Model | 2 | 2.4 | 2.6 | 3 | 3.2 | 3.6 | |

| parameters | |||||||

| mm | 2000 | 2400 | 2600 | 3000 | 3200 | 3600 | |

| Diameter of furnace | |||||||

| mm | 13-25、25-50 | ||||||

| Size of fuel | |||||||

| kg/h | 800-920 | 1200-1400 | 1400-1600 | 2000-2100 | 2100-2500 | 2500-3500 | |

| Fuel consumption | |||||||

| m³/h | 2500-3000 | 3600-4200 | 4200-5200 | 6000-6500 | 6500-8000 | 8000-11000 | |

| Coal gas output | |||||||

| KJ/ m³ | Upper | 7100-7500 | 7100-7500 | 7100-7500 | 7100-7500 | 7100-7500 | 7100-7500 |

| Thermal value of coal | Part | ||||||

| Lower part | 5016-5643 | 5016-5643 | 5016-5643 | 5016-5643 | 5016-5643 | 5016-5643 | |

| Mixing | 6186-6690 | 6186-6690 | 6186-6690 | 6186-6690 | 6186-6690 | 6186-6690 | |

| ℃ | Upper part | 100-150 | 100-150 | 100-150 | 100-150 | 100-150 | 100-150 |

| Outlet temperature of coal gas | Lower part | 500-600 | 500-600 | 500-600 | 500-600 | 500-600 | 500-600 |

| outlet pressure:K Pa | Upper part | <1 | |||||

| Lower part | <1.5 | ||||||

| K pa | 5月6日 | ||||||

| Air pressure of furnace bottom | |||||||

| ℃ | 50-65 | ||||||

| Saturation temperature | |||||||

| K pa | 98/294 | ||||||

| Steam pressure of water jacket | |||||||

| Kg/h | 300 | 400 | 450 | 500 | 550 | 650 | |

| Steam output of water jacket | |||||||

| r/h | 2.97 | 2.3 | 1.7 | 1.5 | 1.5 | 1.5 | |

| Rotary speed of ash basin | |||||||

| KW | 3 | 4 | 5.5 | 5.5 | 5.5 | 7.5 | |

| Transmission power of ash basin | |||||||

| KW | 2.2 | ||||||

| Power of hydraulic station | |||||||

| K pa | 98/294 | ||||||

| Gland steam pressure of fire detector | |||||||

| Fuels available | Non adhesive and weakly bonded bitumite and anthracite; the quality of coal should conform with GB/9143. | ||||||

| mm | Upper part | DN250 | DN300 | DN300 | DN400 | DN400 | DN600 |

| Diameter of coal gas outlet | Lower part | 400x400 | 766x766 | 766x766 | 866x866 | 866x866 | 1000x1000 |

| Diameter of blast pipe at furnace bottom | DN250 | DN300 | DN300 | DN400 | DN400 | DN600 | |

| KW | 40 | 55 | 70 | 100 | 150 | 190 | |

| Total power | |||||||

| Slag discharge form | Wet type, automatically discharge slag; | ||||||

General heat source

suitable for a variety of heat sources, not restricted by heat source

Low operating costs

Low energy consumption and low operating costs

Environmental protection

use various of dust collectors to meet local environmental standards

Quality control

High-precision process equipment, strict quality control

Support customization

customized equipment according to customer needs

Technical guidance

professional and technical personn-el on-site guidance operation

Automatic operation

automatic operation, simple operati-on and saving manpower