The process to remove free moisture is called drying and the process to remove crystal moisture is called calcining. Both natural gypsum and industrial by-product gypsum (such as desulfurized gypsum and phosphogypsum) exist in the form of calcium sulfate dihydrate, with two crystal water in the molecular formula, and some free water is attached to the surface. Taeda MGT gypsum dryer uses direct airflow heating to dry water-containing gypsum. The direct airflow method is a set of new gypsum drying process developed by TAEDA based on the "gas-solid cyclone" drying technology with extremely high heat and mass transfer efficiency. This process is suitable to dry natural gypsum before grinding. Its internal reasonble structure makes it also very suitable for drying industrial by-product gypsum (such as desulfurized gypsum) with high viscosity and easy bonding. Taeda gypsum effectively avoids problem of material accumulation and unsmooth flow in dryer. Wet materials can get adequate drying to reach good drying effect.

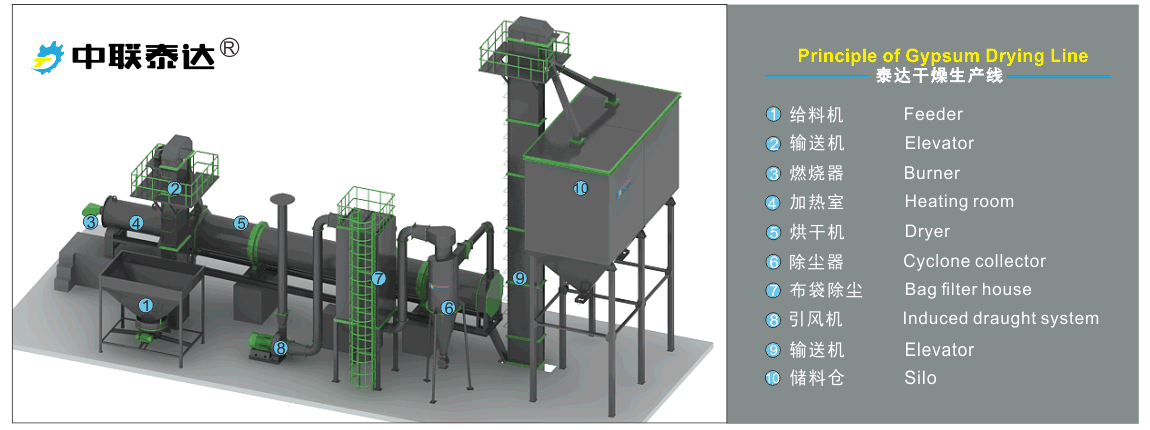

This series gypsum dryer is composed of heat source equipment, drying equipment, transmission parts, transportation device, dust removal plant, induced air system, electronic control equipment and other several parts. Gypsum dryer is applied for drying various gypsum materials in construction, chemical and other industries.

Taeda new gypsum dryer can match with various heat source like flue gas, coal gas, steam and other optional hot air, which makes whole gypsum drying system can meet different drying demands of different customers.

Taeda new gypsum dryer is featured in compact structure and low investment cost. Whole process parameters hold strong reliability because of previous test and preproof. Whole system holds very high output capacity, small flow resistance; Whole system can be operated easily and conveniently.

After times' upgrading and improvement, energy consumption of Taida dryer is much less than common drying machine. During drying process, Taeda gypsum dryer consumes less energy and heat value needed is not over 350 thousand Kcal for per ton gypsum. If there is flue exhaust heat available for customer, low-temperature flue gas from power plant can also be used.

Taeda new gypsum dryer is designed with reasonable structure and scientific configuration. It is featured in small material resistance, long service life, stable running, easy operation and low malfunction rate.This machine is characterized by good abrasive resistance. Therefore, it has a long service span.

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |