【Feeding size】:

【Feeding moisture】: 20%-40%(Internal+external)

【Capacity】: 0.5-70t/h

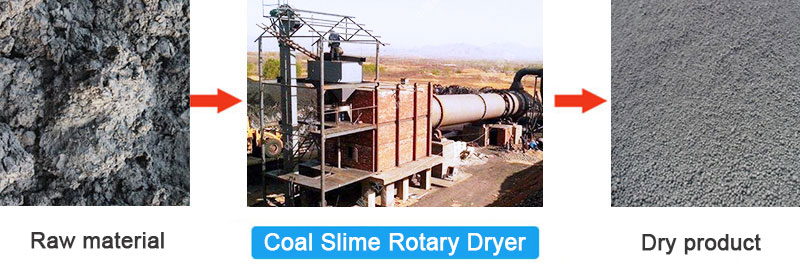

【Application】: Coal slime dryer Can be used to dry coal slime, peat, clean coal, washed coal, mixed clean coal, lignite, raw coal, flotation clean coal, tailings and other similar viscous materials.

Coal slime is coal washing process of industrial waste residue. Due to coal slurry with high moisture content, high viscosity, high water, and low calorific value such many other adverse conditions, it is difficult to realize industrial use, based on the coal slime industry market and the characteristics of coal slurry, through many times technical research and practice, Zhengzhou Taida company developed a new generation of coal slime drying system meticulously, drying product moisture is less than 15%, the calorific value of coal can achieve 2800-4200 kcal/kg,it is a good fuel of coal boiler. This set of equipment technology is mature, stable running, convenient operation and maintenance.

As professional coal slime dryer manufacturer, Zonelion Taeda takes transportation convenience into consideration during manufacturing process. Compared with other similar system, Taeda coal slime dryer can save 30% installation speed. At present, Taeda coal slime dryer has been widely applied in many coal enterprised different regions like Yunnan, Guizhou, Ningxia, Inner Mongolia, Shandong, Shanxi, Henan, Hebei, Anhui, Heilong River, Jiangsu and Indonesia. It has brought great benefits for both society and economy.

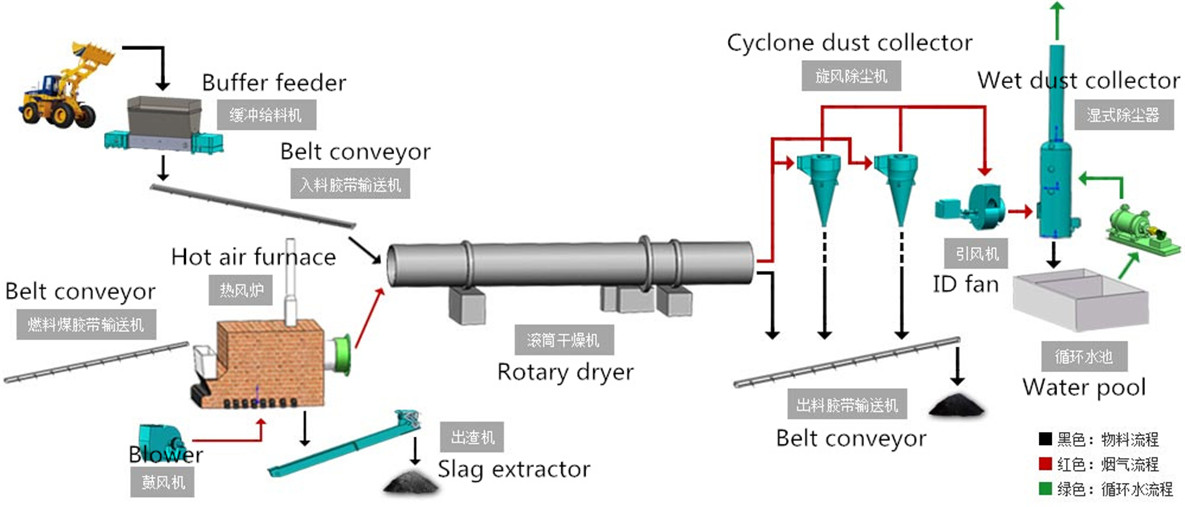

Taeda coal slime dryer is installed with new feeding and discharging device, which avoids clogging, discontinuous, uneven and material returning phenomena. Correspondingly, dust collecting load is reduced. Taeda coal slime dryer adopts self-aligning tug device, which makes the match of supporting wheel and rolling ring in linear contact. Thus, both abrasion and power loss can be decreased.

Taeda coal slime dryer is featured in high thermal efficiency, low energy consumption, high overload resistance, large capacity, less fuel consumption and low drying cost. It adopts fair current drying mode where flue gas and wet materials flow to dryer from same end. High temperature flue gas helps realize high evaporation capacity. Meanwhile, temperature at dryer outlet is low and thermal effciency is high.

During drying process, Stable and thorough section material curtain can be formed. Mass and heat exchange is done fully. New internal structure enhances cleaning and heat conduction function to dispersed materials. Wall sticking in drum is eliminated. New design holds better adapability to different moisture and stickness.

| Model | Drum diameter(M) | Drum length(M) | Drum slope(%) | Motor power(kw) |

Drum rpm (r/min) |

Occupation area(m²) |

| TDGT-12100 | 1.2 | 10 | 3-5% | 7.5 | 3-8 | 100 |

| TDGT-15120 | 1.5 | 12 | 3-5% | 10 | 3-8 | 150 |

| TDGT-15150 | 1.5 | 15 | 3-5% | 18.5 | 3-8 | 200 |

| TDGT-18120 | 1.8 | 12 | 3-5% | 11 | 3-8 | 260 |

| TDGT-22120 | 2.2 | 12 | 3-5% | 18.5 | 3-8 | 260 |

| TDGT-22140 | 2.2 | 14 | 3-5% | 18.5 | 3-5 | 300 |

| TDGT-22160 | 2.2 | 16 | 3-5% | 30 | 3-5 | 300 |

| TDGT-24140 | 2.4 | 14 | 3-5% | 30 | 3-5 | 350 |

| TDGT-24180 | 2.4 | 18 | 3-5% | 37 | 3-5 | 400 |

| TDGT-24220 | 2.4 | 20 | 3-5% | 37 | 3-5 | 450 |

| TDGT-30200 | 3.0 | 20 | 3-5% | 55 | 3-5 | 500 |

| TDGT-30220 | 3.0 | 22 | 3-5% | 75 | 3-5 | 500 |

| TDGT-40250 | 4.0 | 25 | 3-5% | 210 | 3-5 | 800 |