Clay is a kind of soil with viscosity and low sand content. Clay itself has the characteristics of plasticity, bonding, thixotropy, shrinkage, and sintering. Taeda clay dryer is widely used in industry, medicine, and ceramics aspects. With the more and more development for clay properties, clay dryer holds more and more application for clay drying.

Clay dryer is a developed by Taeda based on features of clay and customer's real demands. It isa new clay drying equipment which adopts new drying technology suitable for clay drying. There is cleaning and dispersing structure suitable for clay and similar materials, which gurantees smooth large scale drying work and stable final moisture. It can realize qualifed moisture one step. After years' marketing, customers give feedbacks like good drying effect, long service life and less exhaust emission. After drying by Taeda clay dryer, final clay dryer holds good quality and it can meet quality of different customers.

Aimed at features of clay, Taeda adopts new rational design suitable for drying clay and similar materials. With crushing and cleaning device, Taeda clay dryer can reduce moisture of clay materials to lower than 5% from 25% one time. Whole system is featured in large capacity, low energy consumption and low running cost.

Taeda clay rotary drum dryer adopts automatic centralized control, which makes dryer run continuously. Limestone materials are dispersed fully inside dryer and fully contact with hot air. Thus, both drying effect and drying ability are good. It adopts seal structure which can effectively avoid dust leak and noise pollution, which can greatly improve working environment of clay dryer.

Taeda clay dryer adopts abrasion resistant materials for drum which makes service life longer. Inclined new design dryer drum is beneficial for drying and thermal utilization. Lifting plates can make clay material evenly scatter in drum. Clay material can fully contact with hor air so that to improve drying efficiency and reduce energy consumption.

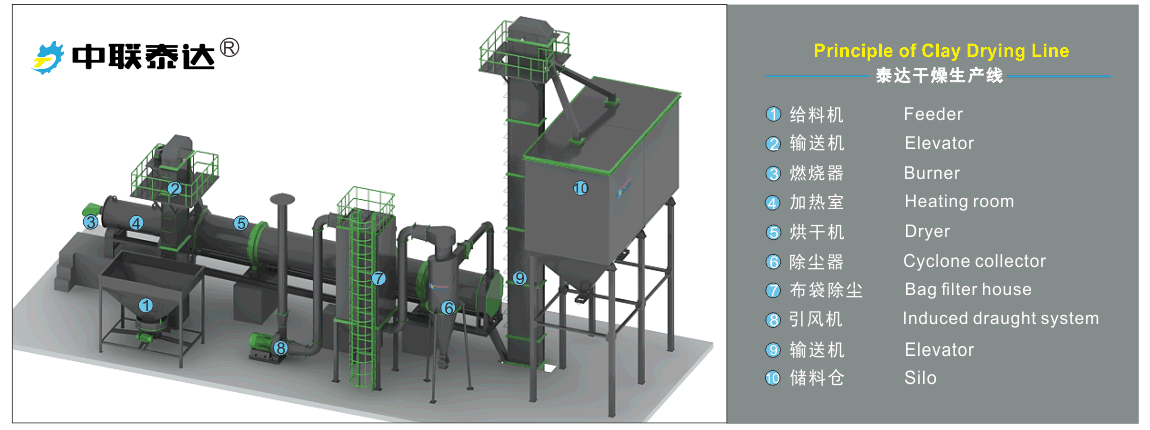

Whole drying system holds flexible configuration. We can configure hopper, feeder, heat source, conveying, dust collecting, product conveying and water scrubbing device. Professional team provides one-step service amd customizes suitable equipment ba

| Item |

Gradient (%) |

Rotational speedr/min) | Inlet air temperature(℃) | Capacity (t/h) | Power(kw) |

| MGT600 | 3-5 | 3-8 | ≤850 | Different Materials Different Capacity. | 3 |

| MGT800 | 3-5 | 3-8 | ≤850 | 4 | |

| MGT1000 | 3-5 | 3-8 | ≤850 | 5.5 | |

| MGT1200 | 3-5 | 3-8 | ≤850 | 11 | |

| MGT1500 | 3-5 | 3-8 | ≤850 | 15 | |

| MGT1800 | 3-5 | 3-8 | ≤850 | 18.5 | |

| MGT2000 | 3-5 | 3-8 | ≤850 | 22 | |

| MGT2200 | 3-5 | 3-8 | ≤850 | 30 | |

| MGT2400 | 3-5 | 3-8 | ≤850 | 37 | |

| MGT2600 | 3-5 | 3-8 | ≤850 | 40 | |

| MGT2800 | 3-5 | 3-8 | ≤850 | 55 | |

| MGT3000 | 3-5 | 3-8 | ≤850 | 75 | |

| MGT3200 | 3-5 | 3-8 | ≤850 | 90 | |

| MGT3400 | 3-5 | 3-8 | ≤850 | 110 | |

| MGT3600 | 3-5 | 3-8 | ≤850 | 150 | |

| MGT4000 | 3-5 | 3-8 | ≤850 | 190 | |

| MGT4200 | 3-5 | 3-8 | ≤850 | 200 | |

| MGT4500 | 3-5 | 3-8 | ≤850 | 260 |