Capacity: 3-40t/h

Working mode: 24h/day

Application range: Mainly used to suppress difficult molding powder materials like many kinds of mineral powder, metal powder, coal powder, coke powder and other materials.

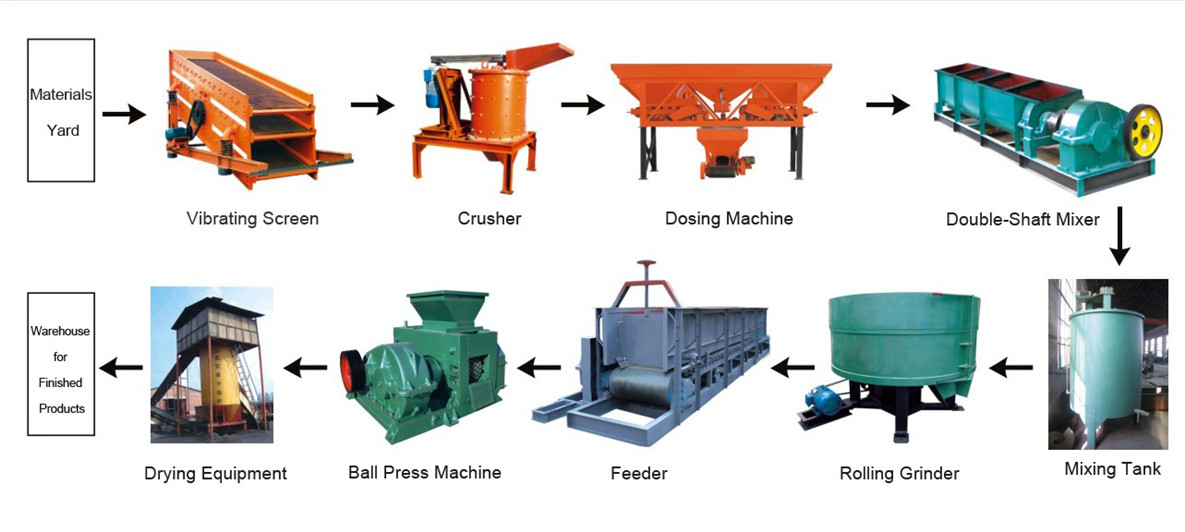

The ball press machine line or the briquette machine line (with other names of ball press machine equipment, pressure ball machine line) is used to press powder materials that are hard to be formed under high pressure by the high strength balls such as coal, quick lime, magnesia powder, copper concentrate, chromium powder, lead and zinc waste, bauxite, non-ferrous metal powder, refractory matter, ceramics etc. It is widely used in the metallurgy industry, chemical engineering industry and refractory matter industry.

Taida briquette machine is proud of that the finished briquettes come with high intensity, great convenience for transportation and various shapes. Custom-made shape is also available. Additionally, the briquettes made by this nonferrous metal powder forming equipment can be used in blast furnace process and metal smelting as chemical and smelting auxiliary material. Since that, this briquette making machine has found wide application in coal industry, metallurgy industry, chemical industry, etc. To be specific, the steel plants can supply mill scale briquettes made using this briquetting equipment to chemical plants for manufacturing ferrosilicon. Aluminum briquettes can be put into smelting furnace for extracting aluminum. Fluorite briquettes can be used as cosolvent for making steel.

Final Briquettes:

1. Shape: can be round, pillow, oval.

2. Size: changeable size 25mm-60mm, made according to clients requests.

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Model | TAE-4 | TAE-6 | TAE-8 | TAE-10 | TAE-15 | TAE-20 | TAE-30 | TAE-40 | |

| Production | Hour | 3-4T/h | 6T/h | 8T/h | 10T/h | 15T/h | 22T/h | 30T/h | 40T/h |

| Annual | 10000T | 20000T | 25000T | 30000T | 50000T | 100000T | 200000T | 300000T | |

| Roll Width | 250mm | 240mm | 220mm | 300mm | 336mm | 630mmA | 720mmA | 800mmA | |

| Roll Diameter | 360mm | 400mm | 450mm | 500mm | 650mm | 650mm | 750mm | 850mm | |

| Powder | 7.5-11KW | 11-15KW | 15-18.5KW | 18.5-30KW | 22-45KW | 30-55KW | 55-90KW | 90-130KW | |

General heat source

suitable for a variety of heat sources, not restricted by heat source

Low operating costs

Low energy consumption and low operating costs

Environmental protection

use various of dust collectors to meet local environmental standards

Quality control

High-precision process equipment, strict quality control

Support customization

customized equipment according to customer needs

Technical guidance

professional and technical personn-el on-site guidance operation

Automatic operation

automatic operation, simple operati-on and saving manpower