【Production Capacity】: 3-50TPH

【Motor Power】: 22-110kw

【Roller Diameter】: 476-1000mm

【Roller Width】: 210-650mm

【Roller Material】: 65Mn/9Cr2M0

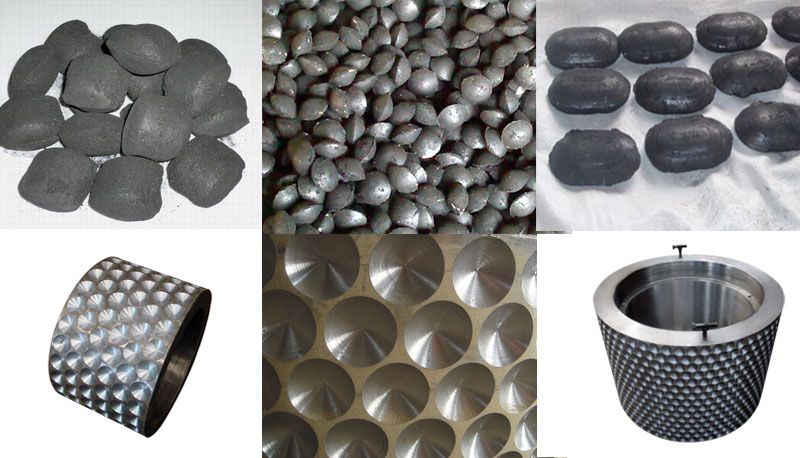

Manganese ore powder briquetting machine is also known as manganese ore powder briquette press machine,this type press machine using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever and unique hydraulic system, for this ,it can improving the briquetting rate and strength.

Main features of Taeda manganese powder ball press machine

1.Long bearing lifetime and save work force.

2.Good quality roller material with 65Mn/ 9Gr2Mo.

3.Unique hydraulic system and high briquettes ratio.

4.Suitable for wet powder and product quality is good.

Our guarantee of manganese powder coal ball press machine

We have an excellent team work, for this we can guarantee briquette press machine quality and punctual delivery. When the briquetting machine in working time, we can guarantee the capacity you need. For the wearing parts, we can provide the parts with lower price for whole using life.

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

|

Model |

Roller Dia.

(mm) |

Roller Width

(mm) |

Motor Power

(kw) |

Shaft Speed

(r/min) |

Reducer Model |

Capacity (t/h) |

Roller Material |

|

TD-476 |

476 |

210 |

22/1.5 |

15 |

ZQ500 |

3-6 |

65Mn |

|

TD-476 |

476 |

260 |

30/1.5 |

15 |

ZQ650 |

4-8 |

9Cr2M0 |

|

TD-500 |

500 |

300 |

30/1.5 |

15 |

ZQ650 |

5-9 |

65Mn/9Cr2M0 |

|

TD-650 |

650 |

336 |

45/1.5 |

15 |

ZQ750 |

8-15 |

65Mn |

|

TD-672 |

672 |

275 |

75/1.5 |

13 |

ZQ1000 |

8-15 |

9Cr2Mo |

|

TD-750 |

750 |

400 |

55/1.5 |

13 |

ZQ850 |

15-20 |

65Mn/9Cr2Mo |

|

TD-850 |

850 |

500 |

75/1.5 |

10 |

ZQ850 |

20-30 |

65Mn/9Cr2M0 |

|

TD-1000 |

1000 |

650 |

110/1.5 |

10 |

ZQ1000 |

30-50 |

65Mn/9Cr2M0 |