Capacity: 50-150t/day

Working Mode: 24h/day

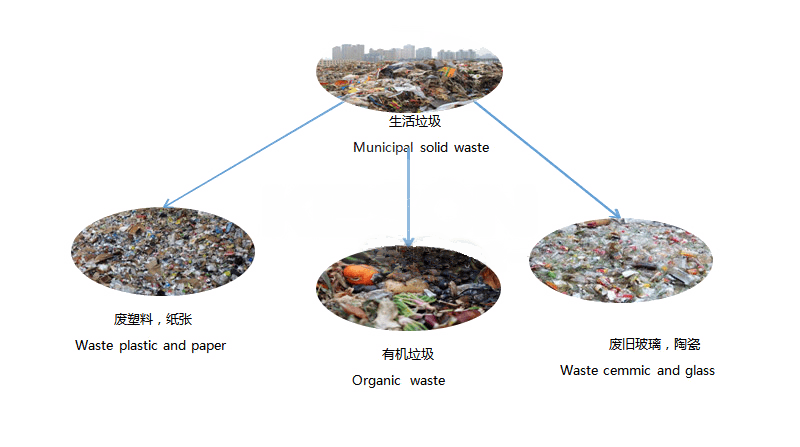

Applicable Material:Construction wastes and domestic wastes

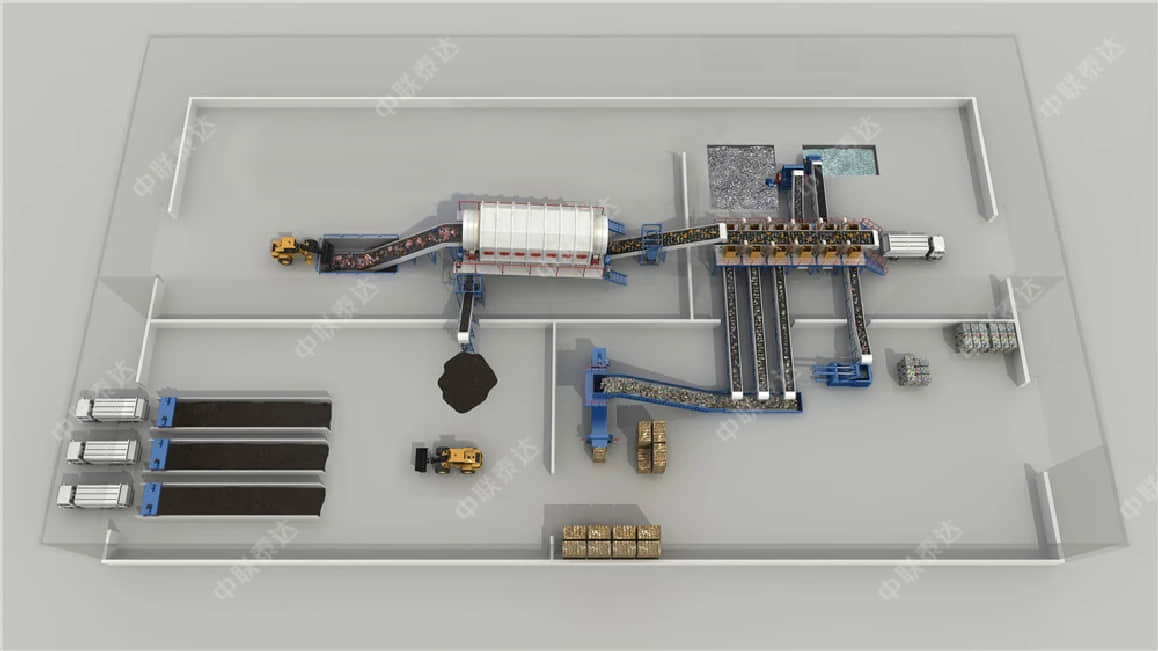

With the development of urbanization, construction wastes, decoration wastes and domestic wastes have become burden of sustainable development aim. Wastes sorting become an urgent issue to solve. Taeda comprehensive wastes sorting recycling production line contains feeding, screening, iron removing, manual sorting and packing into a whole. Wastes sorting has become a new style for city wastes disposal. Taeda new wastes sorting line can separate and recycle renewable resources like paper, stone, sand, plastics, knitting, ceramics, glass, ring-pull can, metal and tile.

Taeda wastes sorting line is characterized by high capacity and stable performance. It consists of mature wastes sorting equipment. At present, this production line has been successfully applied for wastes sorting work in many places and enjoy great popularity. If you also have concern for wastes disposal, please feel free to contact with us and we will customize superior wastes sorting proposal and equipment.

C&D waste screening sorting recycling line can be applied to sorting various wastes, like construction and domestic wastes.

Taeda construction and domestic waste sorting system work with feeder, trommel screen, iron remover and baling machine, which makes whole line working efficiently.

Whole system adopts reasonbable design and supoerior texture, which makes less malfunction, easy operation and convenient maintenance. We can also provide complete service containing installation, training, operation and trusteeship.

Construction and domestic waste sorting line can maximally classify hazardous wastes. Useful resources like stone, plastic, knitting, paper and bottle can be recycled and used for other aspects.

Taeda solid wastes sorting line is mainly applied to sorting, seperation and recycling of constfuction wastes and domestic wastes. It is your Whole system mainly consists of five major process which are feeding, screening, deironing, manual sorting and baling.

| C&D Wastes Screening Sorting Recycling Line Consists of five major parts. | |||||

| Project Section | Box Feeder | Trommel screen | Iron Seperator | Sorting Platform | Baling Machine |

| Model | BF8.20-BF12.40 | TDTS1500-TDTS2500 | B500-B800 | 4-8/people | 140T-180T |

| Capacity | 50-150t/day | ||||

| Auxiliary Equipment | In order to make sure smooth running of whole system, besides above major equipment, we can also configure you necessary auxiliary equipment, like bucket elevator, conveyor, silo, packing machine, electrical control and etc. | ||||

| Notes: Please don’t hesitate to contact us for technical details and equipment configuration proposal. | |||||

General heat source

suitable for a variety of heat sources, not restricted by heat source

Low operating costs

Low energy consumption and low operating costs

Environmental protection

use various of dust collectors to meet local environmental standards

Quality control

High-precision process equipment, strict quality control

Support customization

customized equipment according to customer needs

Technical guidance

professional and technical personn-el on-site guidance operation

Automatic operation

automatic operation, simple operati-on and saving manpower