Introduction

E-style biomass dryer is developed based on TDQ hot air stirring dryer. Meanwhile, it absorbs advantages of fluid bed, airflow dryer and rotary dryer. High output, small occupation area, uniform drying and high efficient are representative feature of E-style biomass drying technology. E-style biomass dryer is regarded as star for fermented feedstuff drying. Our customers in fermented feedstuff industry are scattered around whole country. Many of them refer to help of our E-style biomass dryer after using triple pass dryer, rotary dryer and flash dryer. Because moving mode of E-style dryer is similar to that of rotary dryer, many new customers may ask the difference between E-style dryer and common rotary dryer. Today I explain the doubts here in details.

In terms of appearance, E-style biomass dryer is like rotary dryer whose both internal and external drum rotate.

It is correct. Its both internal and external drum rotate. But, there is essential difference between them two.

First: Difference of feeding mode: For common drum dryer, raw materials are fed into dryer from top of feeding gland head. E-style biomass dryer adopts axial forced feeding which can guarantee best feeding uniformity. Crescent air inlet pipe can prevent product burnt and make sure drying efficiency.

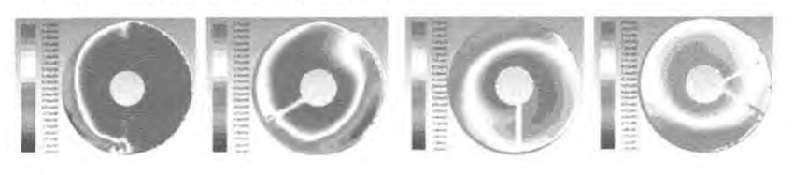

Second: internal rotary wing shaft is also rotating, which guarantees that materials are presenting floating material curtain. In addition, there are different structures set on rotary wing shaft so that different zones can finish different work. Owing to involving technical secrecy, we will not do further explanation here. Simply, rotary wing shaft can guarantee floating state of raw material in dryer. Please refer to following pictures for details.

Third: discharging mode is not same. For rotary drum dryer, materials are discharged naturally. Partial light material absorbs features of airflow dryer. It is like cone discharging outlet design of Taeda E-style biomass dryer. But, please remember that arrangement of Taeda cone discharging outlet decides proper drying state. Final moisture reduction is finished through pulse drying unit, which is key point for saving energy consumption.

Zero horizontal thrust, no inclination

From appearance, there is one essential difference between E-style biomass dryer and rotary drum dryer. E-style biomass dryer is arranged in horizontal direction and there is no inclination. Material movement doesn’t rely on inclination of drum. In this way, during running process, there is no horizontal thrust, so there is less abrasion caused to big gear, support roller and roller ring. Generally, spare parts for Taeda MGT and MED dryer should be replaced in every 5 years. Service life for E-style biomass dryer even reaches to 7 years. Correspondingly, customers can save money for spare parts purchasing and save time for equipment maintenance. Therefore, E-style biomass dryer is a kind of scientific and efficient drying system.

Pulse drying unit is major part for E-style biomass dryer

In above article, we have introduced that final moisture reduction is finished in pulse drying unit, which helps save heat. Therefore, please noted that pulse drying unit is important part for E-style biomass dryer. E-style biomass dryer is not a simple rotary object and it is composed of multiple modular drying units. Before launching to market, Taeda E-style biomass dryer is called new type combination dryer. Have you understood the difference between E-style biomass dryer and common rotary dryer?

If you want to know more details about E-style biomass dryer, welcome to follow our official Tik Tock account or contact us via wechat/whatsapp. We will update new articles to introduce good performance of our E-style biomass dryer for difference fermented materials.

Copy reserved and reproduction prohibited.

Relative news