【Material layer】:

【Working pressure】: ≈0.5Mpa

【Feeding moisture】: 40-94%

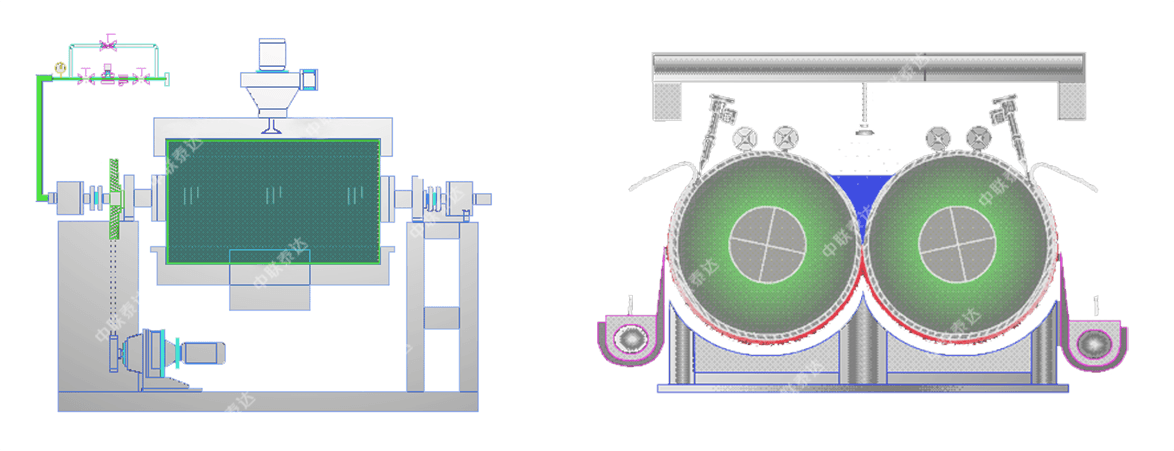

TAIDA GERG Yeast Rotary Drum Scraper Dryer is a kind of continuous drying equipment which adopts internal heating conduction.It can use steam and hot oil as fuel.During running process, drum will run continuously and gradually. Materials with certain thickness adhere to dryer's lower chute. Heat will be conveyed to to rotary drum's inner wall through pipe and transferred to drum's external wall. Then, these heat will be led to material film, which will evaporate and dewater the moisture in raw materials. In this way, wet materials will be dried. Dried materials will be removed by scrapper installed on rotary drum surface and dumped to conveyor under scraper. Through conveying device, dried products will be sent to packing process.

TAIDA GERG rotary drum dryer is especially suitable to dry paste materials with certain stickiness. Typical material for TAIDA GERG dryer is yeast, starch, rice flour, oatmeal and potato flour. It is widey applied to dry sticky and heat-senstive materials from chemical, dyestuff, medicine making, food, metallurgy and yeast industry.

GERG Yeast Dryer consumes short drying period and drying work can be finished in 7-30 seconds. Products will not be affected by high temperature, therefore GERG Yeast Dryer is suitable for drying heat-sensitive materials. Materials will form thin film on dryer drum. Its thermal efficiency can reach 70% to 80%.

There will be almost no product residues remaining in dryer. therefore GERG Yeast Dryer is also suitable for small capacity drying task. Cleaning task for GERG Yeast Dryer is convenient and materials to be dried can be changed any time. No need to worry about pollution caused during drying different batch materials.

GERG Yeast Dryer can run continuously and product from it hold stable quality. Customers can get uniform dried materials. Because it needs no wind to evaporate moisture, exhaust gas will not bring out materials. Corresponding, GERG Yeast Dryer will cause almost no burden to environment.

Drum of GERG Yeast Dryer is a hollow metal cylinder whose surface is deeply processed to be clean and polished. Dryer drum rotates to the axial under gear driving devices (gear drive) in an adjustable rate. Thus, GERG Yeast Dryer conumes less quick wear parts and costs lower maintenance expense.

| Specifications | Drum dimensions | Drying area | Drying capacity | Heating mode | Steam consumption | Motor power | Overall dimensions |

| GERG600 | φ600×800 | 1.12 | 40-70 | Steam/electricity | 100-175 | 2.2 | 1700*800*1500 |

| GERG700 | φ700×1000 | 1.65 | 60-90 | 150-225 | 3 | 2100*1000*1800 | |

| GERG800 | φ800×1200 | 2.226 | 90-130 | 225-3258 | 4 | 2500*1100*1980 | |

| GERG1000 | φ1000×1400 | 3.30 | 130-190 | 325-475 | 5.5 | 2700*1300*2250 | |

| GERG1200 | φ1200×1500 | 4.24 | 160-250 | 400-625 | 7.5 | 2800*1500*2450 | |

| GERG1400 | φ1400×1600 | 5.28 | 210-310 | 525-775 | 7.5 | 3150*1700*2800 | |

| GERG1600 | φ1600×1800 | 6.79 | 270-400 | 675-1000 | 11 | 3350*1900*3150 | |

| GERG1800 | φ1800×2000 | 8.48 | 330-500 | 825-1250 | 15 | 3600*2050*3500 | |

| GERG1825 | φ1800×2500 | 10.6 | 420-630 | 1050-1575 | 15 | 4100*2650*3500 | |

| GERG2000 | φ2000×2500 | 11.775 | 510-840 | 1200-1740 | 18.5 | 4100*2650*3500 | |

| GERG2025 | φ2000×3000 | 14.13 | 610-990 | 1380-2205 | 18.5 | 4200*3520*3700 | |

| GERG2500 | φ2500×3000 | 17.6625 | 810-1240 | 1750-2500 | 18.5 | 4200*3900*4000 | |

| GERG2540 | φ2500×4000 | 23.55 | 920-1650 | 2310-3465 | 22 | 5300*3900*4000 |