【Feeding size】:

【Feeding moisture】: 35-85%

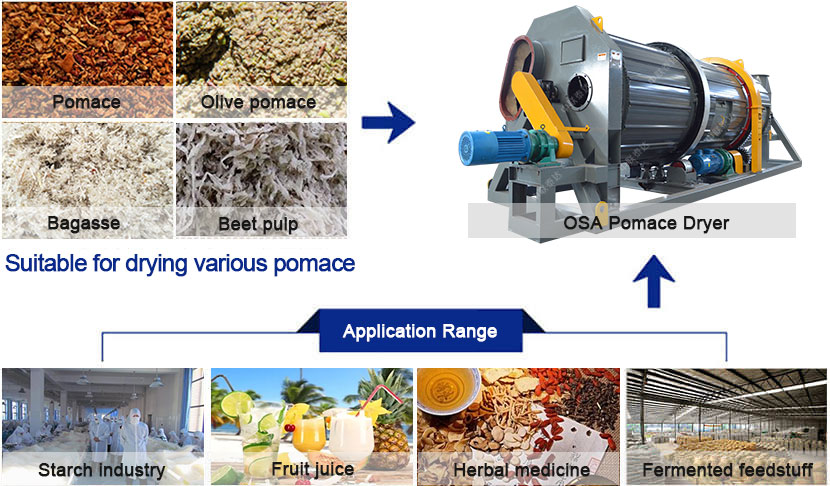

【Application range】: Suiitable for feedstuff, agriculture, starch, medicine, animal husbandry and environment protection.

Taeda® pomace dryer can be used for pomace, apple pomace, olive pomace, vinegar pomace, citrus pomace, bagasse, fermented pomace, pericarp/pulpa/seed/stem/chaff materials. Pomace dryer is a kind of series specially designed for high moisture biomass material. It is featured in high capacity, large occupation area, low energy consumption and stable running performance. It is third generation dryer designed for pomace drying. During drying pomace, its capacity is higher than single drum dryer and footprint is smaller than triple pass dryer. Its running cost is much lower than steam tube bundle dryer and its thermal efficiency is pretty high.

Pomace dried from Taeda OSA rotary drum holds good taste and color, which improves palatability and feedstuff intake amount. Taeda pomace dryer solves many customers' concern that pomace with high viscosity will cause wall sticking, caking and blocking problem. Then, drying equipment cannot work normally and causes loss to users' interests. Pomace dryer desgined by Taeda can reduce pomace moisture to 12% one time. Final product from our pomace dryer holds good color and quality. It is an energy saving and environment protection dryer enjoying great popularity among customers. At present, Taeda pomace dryer has been widely applied for multiple beverage plant and juice plants.

Taeda third generation pomace dryer is especially designed for drying various high moisture pomace materials like olive pomace, bagasse, olive pomace, fermented pomace, citrus pomace, pomace, beet pulp ad etc. Taeda pomace dryer is characterized by large capacity, low energy consumption, no wall-sticking and no over-drying.

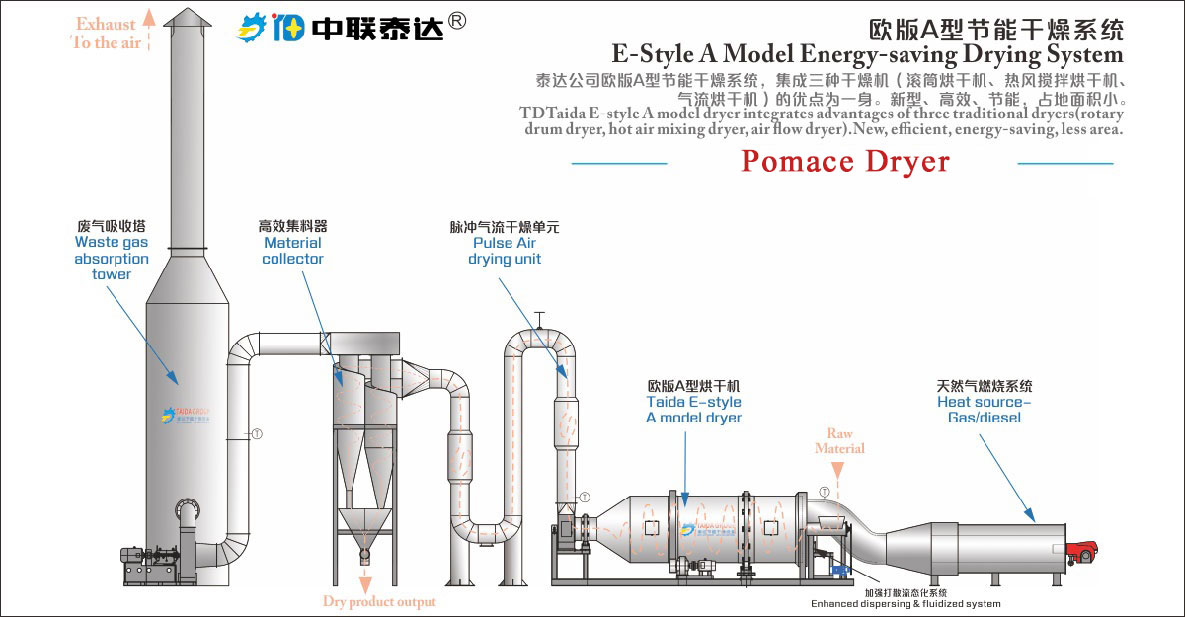

High speed dispersing system is installed on drying cross section of dryer. Matched with suitable air accelerator and vortex generating device, Materials will form boiling curtain with vortex hot air, which make sure efficient process for heat exchanging, evaporation, dewatering and cooling. Meanwhile, wall sticking and over-burning phenomenon are avoided.

Relying on scientific design, for same capacity, total length of OSA pomace dryer is only half of triple pass dryer and one third of common drum dryer. Therefore, OSA dryer holds small footprint and its heat radiating area is smaller than common dryer. With high energy utilization and low thermal loss, OSA dryer is more energy saving.

Whole drying system holds flexible configuration. We can configure dewatering equipment, feeder, crusher, heat source, conveying, dust collecting, elevation, cooler and packing unit. Professional team provides one-step service amd customizes suitable equipment ba

| Model | Transmission motor power | Fan power | Dispersing power | Weight | Overall dimension(W*L*H) |

| TDJZⅠ | 4-4.5 KW | 7.5 KW | 3KW | 6.5t | 1.5×4.5×1.7m |

| TDJZⅡ | 5.5 KW | 11 KW | 4KW | 9.5t | 1.6×5.5×2.0m |

| TDJZⅢ | 7.5 KW | 15 KW | 5.5KW | 12.5t | 1.8×6.5×2.0m |

| TDJZⅣ | 11 KW | 18.5 KW | 5.5KW | 18.5t | 2.4×8.5×2.5m |

| TDJZⅤ | 15 KW | 22 KW | 5.5KW | 24t | 2.6×8.5×2.5m |

| TDJZⅤI | 18.5 KW | 45 KW | 7.5KW | 32.2t | 3.0×10.5×3.0m |

| TDJZⅤII | 22 KW | 75 KW | 11KW | 40t | 3.0×11×3.0m |

| Pomace moisture | Before drying: 25-78%, after drying:≤13 | ||||

| Output capacity | 0.5-16t/h, depends on raw material and moisture content. | ||||