【Capacity】: 1-20t/h

【Screen layer】:1-6 layer

【Mesh number】:2-325

【Machine material】: 304/316/carbon steel

【Grid material】: wood/steel

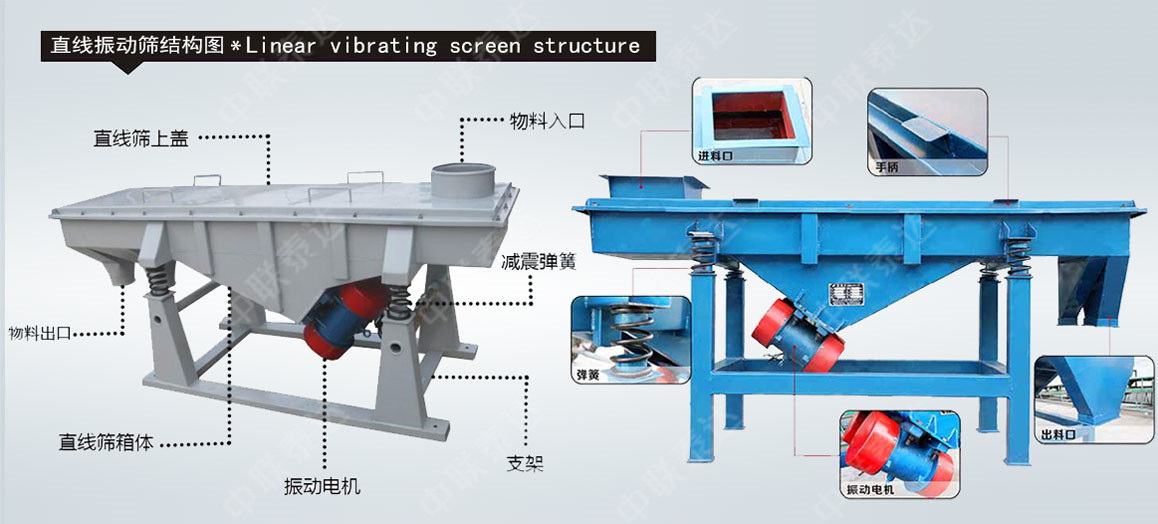

Vibrating screen is a new model of screening equipment with the high efficiency, which can be widely applied in the industries such as mining, coal, metallurgy, building material, smelt and light industry. Vibrating screen which is also can be called linear vibrating screen has the reliable operation, lower energy consumption, lower noise, long lifespan, stable vibration, high screening efficiency and so on. The basic theory of it is mainly by the hammer (uneven hammer) installed in the lower end of the motor shaft, the rotary motion of the motor into a horizontal, vertical, three-dimensional movement of the tilt, then this movement is conveyed to the screen surface. The traveling direction of the raw material can be changed if the angle of the upper and lower portion of the hammer is changed.

Linear vibrating screen takes dual vibration motor drive, when the two vibrating motors do synchronous reverse rotation, the exciting force generated by the eccentric block each other in a direction parallel to the motor axis of the offset, stacked in the direction perpendicular to the motor shaft a force and therefore the sifter's trajectory is a straight line. Two motors shaft relative screen surface inclination, the excitation force and materials from the joint effect of gravity, the materials in the screen surface toss and leap forward for linear motion in order to achieve the purpose of screening and classification of the material. This vibrating screen can be used in the assembly line to reach the automatic work.

Linear vibrating screen takes the vibrating motor as the vibrating energy, which can make the material toss from a sieve, and while the material can be forward for linear motion, and the material can be fed to the feeding opening through the multi-la

Taeda holds 20-year production history and 60-year skllled production team. 95% spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Model | Mesh size | layer | Mesh number | leaning angle of screen | Frequency | Amplitude | Power | Angle of vibration direction | Dimension |

| (mm) | mesh | ° | Times per minute | (mm) | (kw) | (L×W×H)mm | |||

| DZSF515 | 500×1500 | 1-6 | 2-200 | 1-7 | 960 | 3-6 | 2×0.37 | 45-60 | 2140×808×848 |

| DZSF520 | 500×2000 | 2-200 | 1-7 | 960 | 3-6 | 2×0.37 | 45-60 | 2140×808×848 | |

| DZSF525 | 500×2500 | 2-200 | 1-7 | 960 | 3-6 | 2×0.55 | 45-60 | 2750×808×938 | |

| DZSF1020 | 100×2000 | 2-200 | 1-7 | 960 | 3-6 | 2×0.55 | 45-60 | 2219×1320×960 | |

| DZSF1025 | 1000×2500 | 2-200 | 1-7 | 960 | 3-6 | 2×0.75 | 45-60 | 2269×1320×960 | |

| DZSF1030 | 1000×2500 | 2-200 | 1-7 | 960 | 3-6 | 2×1.1 | 45-60 | 3219×1340×1120 |