【Production Capacity】: 3-45TPH

【Motor Power】: 7.5-45kw

【Roller Diameter】: 360-1000mm

【Roller Width】: 250-530mm

【Roller Material】: 65Mn/9Cr2M0

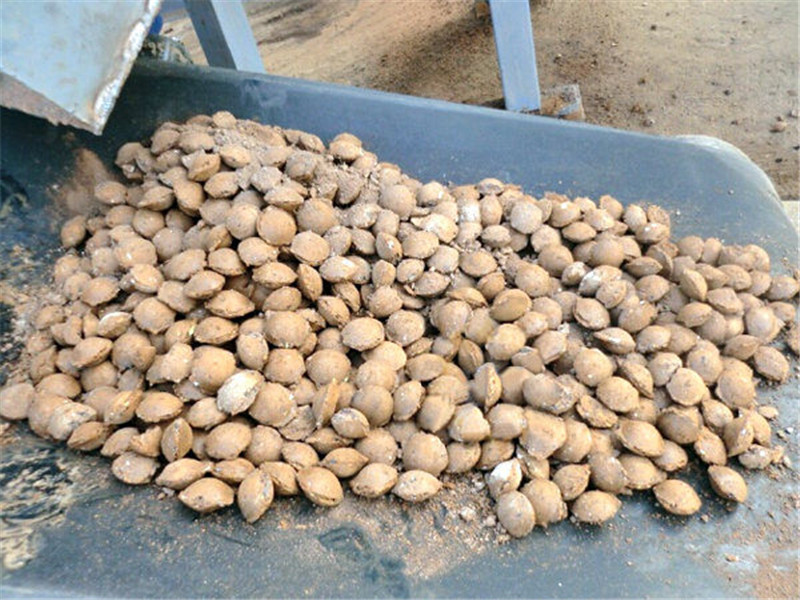

Iron Powder Ball Press Machine is mainly used for high-density metal scrap (scrap iron, copper scrap, aluminum scrap, etc.), granular powder metal powder (iron powder, aluminum powder, copper powder, lead powder, etc.) , metallurgical additives, sponge iron, etc., without adding any binder pressed into the case of cylindrical cakes of high-density block (weight 2-8 kg), the cake density of up to 5T/M3 block above (the different raw materials, press out the cake block density and not quantity is not the same), pressed into the cake pieces can be directly cast furnace use.

Working Principle:

This series of ball press machine will pass the power on to the two pressure roller through the reducer.The two sides and roll rotation, in both the rotating roll,Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger, When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials become a finished product from the powder ball.

After-sale services:

1. We will supply the most suitable crushing plant to customers according to their requirements.

2. Assist clients to prepare for the first construction scheme, we will supply the Machine base drawing and Installation manual.

3. For the Installation, we will dispatch two or three engineers to guide the installation, take the trial test, train their worker, debug the equipment, adjust the capacity etc if you need.

4. The regular inspection and maintenance will be supplied on time.

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Model | Reducer | speed ratio | The dimension of pressing roll | speed of main shaft(r/min) |

Power of motor (kw) |

Output (t/h) |

| TD360-4 | ZQ350 | 1:31.5 | Φ360*250 | 15-17 | 7.5 | 3-5 |

| TD 360-2 | ZQ350 | 1:31.5 | Φ360*250 | 15-17 | 7.5 | 3-5 |

| TD 400-4 | ZQ400 | 1:31.5 | Φ400*250 | 15-17 | 11 | 4-7 |

| TD 400-2 | ZQ400 | 1:31.5 | Φ400*250 | 15-17 | 7.5 | 4-7 |

| TD 430-4 | ZQ400 | 1:31.5 | Φ430*250 | 15-17 | 11 | 5-8 |

| TD 430-2 | ZQ400 | 1:31.5 | Φ430*250 | 15-17 | 7.5 | 5-8 |

| TD 500-4 | ZQ500 | 1:31.5 | Φ500*350 | 15-17 | 22 | 8-10 |

| TD 500-2 | ZQ500 | 1:31.5 | Φ500*350 | 15-17 | 15 | 8-10 |

| TD 650-4 | ZQ650 | 1:31.5 | Φ650*350 | 15-17 | 30 | 12-20 |

| TD 650-2 | ZQ650 | 1:31.5 | Φ650*350 | 15-17 | 22 | 12-20 |

| TD 750-4 | ZQ750 | 1:31.5 | Φ750*380 | 14-16 | 30 | 25-30 |

| TD 850-4 | ZQ850 | 1:31.5 | Φ850*436 | 14-16 | 37 | 35-40 |

| TD 1000-4 | ZQ1000 | 1:31.5 | Φ1000*530 | 14-16 | 45 | 40-45 |