Capacity: 0.5-30t/h

Power: 9.5-37kw

Application range: Suitable to process chicken manure, cattle manure, pig manure, pigeon dung and other poultry manure, straw and other agricultural wastes biogas residue and kitchen garbage into organic fertilizer.

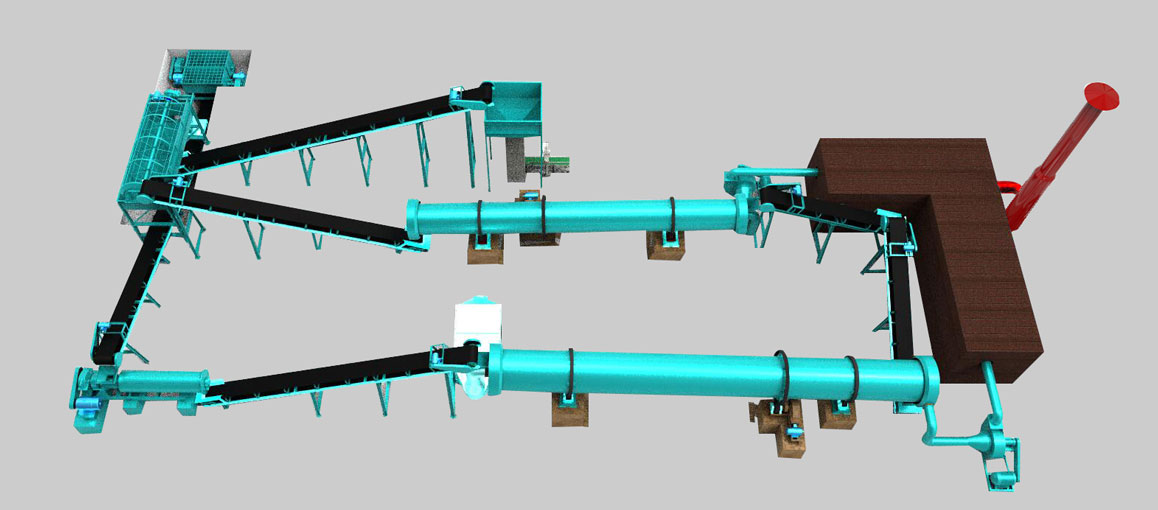

Organic fertlizer production line is always used to process various fermented organic materials into organic fertilizer. This production line mainly regards animal manure and agricultural wastes as major raw material. This production line transfers wastes into useful resources and can protect environment. In short, whole production line can carry out following series work: choose several types fertilizer material; weigh and mix these fertilizers; take binder and finish granulating work in disc granulator or rotary drum granulator; Under rotation in disc or rotary drum, materials will agglomerate into fertilizer particles; Finally, carry out drying and cooling process.

Materials of organic fertlizer production line mainly are animal manure. Taeda organic fertilizer production line is featured in wide application range, short production process, simple structure, less investment and easy operation. It is suitable for small medium sized enterprises. Organic fertilizer production line work process mainly contains 8 units, fermentation, dosing, granulating/pelleting, drying, cooling, screening, coating and packing. According to granulating/pelleting process, it is classified into disc granulating, rotary drum granulating and pin mix granulating production line. No matter which process customer choose, they are mature production process which is featured in wide application and easy operation.

Taeda organic fertilizer production line is an efficient and reliable system for making use of various animal manure and agricultural wastes to produce organic fertilizer. Whole system mainly consists of three major parts, fertilizer drying, fertilizer cooling and fertilizer coating procedure.

Support customization

customized equipment according to customer needs

Technical guidance

professional and technical personn-el on-site guidance operation

Automatic operation

automatic operation, simple operati-on and saving manpower