【Type】: Rotary kiln

【Calcination temperature】: 500-1250℃

【Temperature zone】:1-4 zone

【Heat source】:Electric heating, gas, pellet fuel, etc

【Specification】:φ200mm-φ3000mm, Larger or smaller sizes can be customized

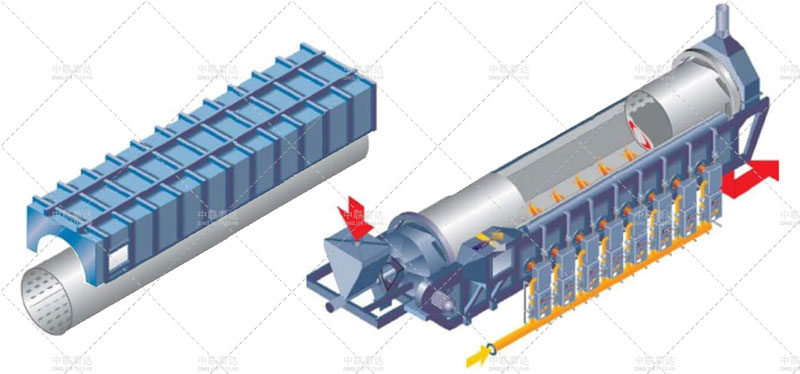

External heating type calcining kiln is a kind of rotary kiln which is suitable for calcining and roasting various medium and low temperature materials. Rotary drum of external heating type calcining kiln is welded by heat-resistant alloy texture furnace tube. It holds good working performance for calcining various materials and require 300 to 1250 calcining temperature. Typical materials are welding materials, catalyst and inorganic powder and etc. Based on 650℃,11000℃ and 1250℃ working temperature, external heating rotary kiln is always classified into middle temperature kiln, high temperature kiln and super high temperature kiln.

For model smaller than TDICA0.6 model, the furnace always adopts electrical heating mode and customers can choose silicon rod, heating coil and heating sling. For model larger than TDICA0.6 model, furnace always adopts fuel heating mode, like gas heating.

Control mode: Drum adopts frequency conversion speed regulation. This kind of kiln always uses integrated base tray and inclination can be adjusted freely. Temperature adjustment can be automatically controlled. Therefore, external heating type calcining kiln is characterized by high output capacity, stable final quality, low energy consumption and less pollution.

| Model |

Output Capacity (kg/h) |

Power | Driving motor | Overal Dimensions (L×W×H) |

| TDICA0.6 | 300-500 | 5.5 | Frequency control | 10*1.1*1.2 |

| TDICA0.8 | 400-600 | 7.5 | 12*1.3*1.5 | |

| TDICA1.0 | 500-800 | 11 | 12*1.5*1.7 | |

| TDICA1.2 | 700-1200 | 15 | 14*1.7*1.8 | |

| TDICA1.5 | 1000-1500 | 18.5 | 14*2*2.2 | |

| TDICA1.6 | 1500-1800 | 22 | 17*2.1*2.2 | |

| TDICA1.8 | 1800-2500 | 30 | 20*2.3*2.5 | |

| TDICA2.0 | 2700-3200 | 37 | 20*2.5*2.7 | |

| TDICA2.2 | 3200-4000 | 45 | 20*2.7*2.8 | |

| TDICA2.5 | 4000-5000 | 55 | 20*3*3.1 | |

| TDICA3.0 | 5000-6000 | 75 | 20*3.5*3.8 |

Strong Processing Ability

Various automatic processing devices makes Taeda has the ability to process 17.5-m length and 100-mm thickness equpment.

Strict Quality Inspection

Taeda carries out strict quality inspection regulations which makes Taeda equipment with high output capacity and high effciency.

Standard Production

Advanced and modern production center makes equipment production process more efficient and Taeda Manufacture reliable.

Superior Process Texture

Taeda adopts superior equipment production materials which guarantees long service life and stable working performance.