【Production Capacity】: 1-5t/h

【Motor Power】: 11-37KW

【Particle size】: :4-10mm

【Feeding size】: <0.3mm

Double roller extruding granulator is our development of a new generation of granulation equipment. The roller extruding granulator makes the products once at the room temperature without drying by production process, two specifications of the capacity for 1-1.5 tons/hour and 1.5 to 3 tons/hour. The equipment is less investment, quick effect, good profit. Complete sets of equipment layout is compact, rational and scientific with the advanced technologies.The roller was first forged and processed from special materials into roughcast, and then machined by numerical lathe and milling machine to be finished product. The roller with the features of rusty resistance, acid and alkali resistance, long service life, not easy to crack .

Double roller fertilizer granulator working principle:

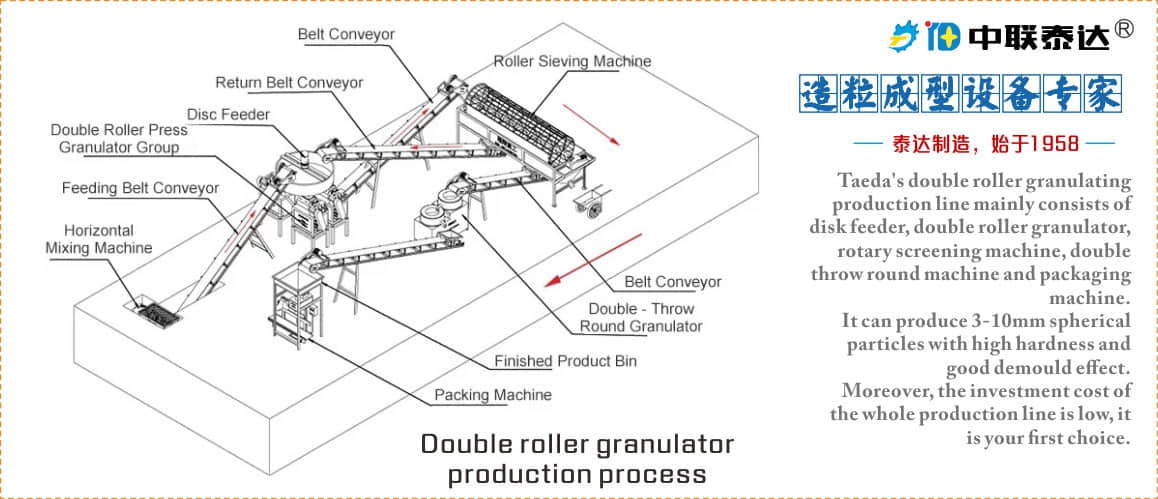

Double roller crusher adopts the design solution of extrusion sliding model,the raw materials pass through double roller,after that,enter into scattering room, come out as granulation, a sieving was mounted at the bottom of the machine, which is customized according to client’s requirement, last, sieve out the granules which is qualified, the rest of materials return to mixer and be re-granulated.

Major applicable materials:

Potassic fertilizers : potassium sulfate, potassium chloride,plant ash etc.

Nitrogen fertilizers : ammonium chloride, ammonium sulfate, ammonium sulphate etc.

Phosphate fertilizer : superphosphate, triple superphosphate, calcium magnesium phosphate

Features of final products:

Unit crushed strength : 10-25N.

Shape of finished products : oval, irregular, wheat shaped, etc,.

Material moisture requirement : not more than 10%

The rate of ball formation : 95%

Output : 1-4t/h ( can combine multiple granulators work together to increase output, see our technical process chart).

Granule size : 3-8mm (popular market granule diameter: 2.8-4mm).

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

|

Model |

TDF-11 | TDF-22 | TDF-37 |

| Product size | 4-10 | 4-10 | 4-10 |

| Power (kw) | 11.5-15 | 18.5-22 | 37 |

| Capacity (t) | 1-2 | 2-3 | 3-5 |

| Dimension (mm) | 1200×750×1400 | 1350×1110×1600 | 1600×1000×1550 |