【Production Capacity】: 1-30TPH

【Motor Power】: 5.5-135kw

【Roller Diameter】: 290-1000mm

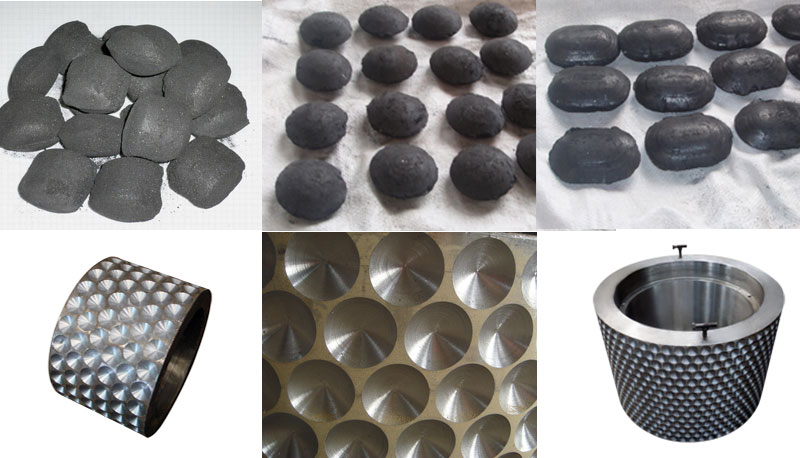

【Applicable material】: Coal dust like brown coal, lignite coal, lean coal, anthracite, peat, and the old brown coal, charcoal fines, coke dust/fines, peacoke, carbon black, carbon dust, carbon electrode,clay, activated carbon, etc.

Coal briquetting machine is mainly used for pressing materials with low water content like brown coal, lignite coal, lean coal, anthracite, peat, and the old brown coal, charcoal fines, coke dust/fines, peacoke, carbon black, carbon dust, carbon electrode,clay, activated carbon.

Taeda coal briquette ore powder ball press machine is a new type of briquette machine with high efficiency, energy conservancy and environment protection.

The performance of the coal briquetting machine is mainly determined by the roller skin of the main engine. This type of coal briquette machine is casted with 65 manganese, and with special heat treatment, its hardness can reach over 58°. The roller skin adopts composite assembly, so that it can be changed when abraded. This briquette machine has a shock absorber which can better protect the equipment from the impact of hard materials. The briquette machine is designed with ball bowl adjustable device to make sure the ball bowls of the two rollers are always in the adjustable range.

Therefore, Taeda coal briquetting machine is a good option for briquetting coal, charcoal and coke.

Taeda holds 20-year production history and 60-year skllled production team. 95& spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

|

Type |

Roll diameter(mm) |

Capacity(t/h) |

Power(kw) |

|

TD290 |

290 |

1-3 |

5.5 |

|

TD360 |

360 |

4-6 |

11-15 |

|

TD430 |

430 |

6-8 |

18.5 |

|

TD500 |

500 |

7-9 |

18.5-55 |

|

TD500H |

500 |

7-9 |

20.7-57.2 |

|

TD650 |

650 |

10-15 |

37-45 |

|

TD650H |

650 |

10-15 |

39.2-47.2 |

|

TD750 |

750 |

15-20 |

75-110 |

|

TD750H |

750 |

15-20 |

78-113 |

|

TD850 |

850 |

20-25 |

90-110 |

|

TD850H |

850 |

20-25 |

93-113 |

|

TD1000 |

1000 |

25-30 |

90-132 |

|

TD1000H |

1000 |

25-30 |

93-135 |

|

Remarks: ba |

|||