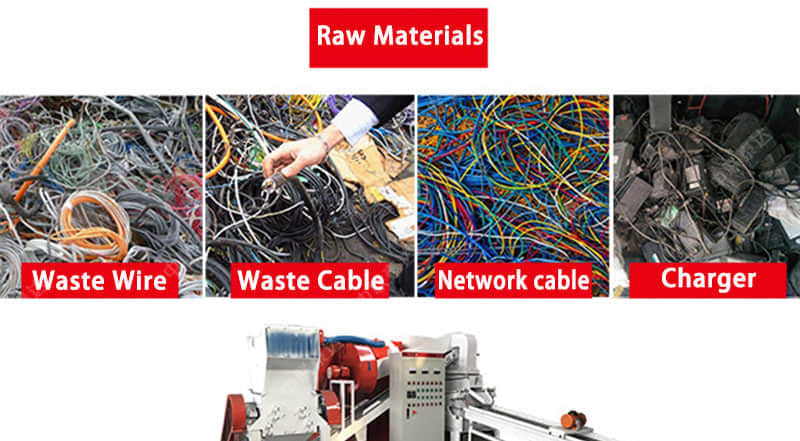

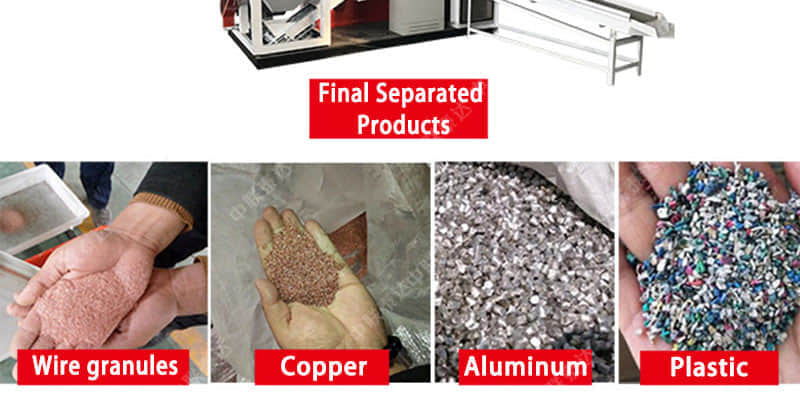

Copper wire seperator is a kind of environmental friendly recycling equipment for processing various waste copper wire, aluminum wire and waste cable. There are more and more waste wires and cables accumulated in daily life. It becomes an urgent issue to deal with these waste wires and cables. Commonly adopted method is to manually separate metal from wire and cables, which not only consumes much labor and time, but also holds lower working efficiency. Aimed at this situation, Taeda Company design a set of new dry type copper wire separating machine to recycle waste cable and wires. During working process, it relies on specific graivity and classification. Because separated coppers are like rice, it is called copper rice machine. There is no need to add any water in the separating process. After primary crusher process, materials are screened and classified to separate metal and plastics

Taeda copper wire sperating system adopt compact structure, intregrated design, no need extra assembly work. With reasbonable layout, customer can start production once receive whole set equipment.

Taeda copper wire seperating machine be used to separate various wires and cables with 0.5 to 20mm diamter

Taeda whole set copper wire seperator adopt PLC control. With intelligent control, whole system will not stop becuase of overload. High automation level consumes less labor force makes operation easier.

Equipped crusher adopt alloy steel with high hardness, which make the copper wire sepatore resist to impact and hold longer service life. Alternating knife shaft makes production more efficient, lower noise and more stable. Whole system is installed with multi-class dust filtering and collecting, almost cause no pollution to environment.

| Model | 400 Model | 600 Model | 800 Model | 1000 Model |

| Processing range(mm) | Φ0.5~Φ20 | Φ0.5~Φ20 | Φ0.5~Φ20 | Φ0.5~Φ20 |

| Specification(m) | 3.2×2.1×2.3 | 7.5×4.8×3 | 8.2×5×3 | 8.8×5×3 |

| Power(Kw) | 27 | 37 | 45 | 55 |

| Capactiy(Kg/h) | 150~180 | 400~600 | 500~700 | 600~800 |