【Feeding size】: 25-100mm;

【Capacity】:5-100t/h

【Application range】: Applied for all kinds of high and medium hardness ores and rocks crushing work in mineral processing, chemical industry, cement, refractory materials, abrasives, building materials and other industrial sectors.

【Applicable material】: Suitable for crushing pebble, granite, basalt, iron ore, limestone, quartz stone, coal gangue and other similar materials.

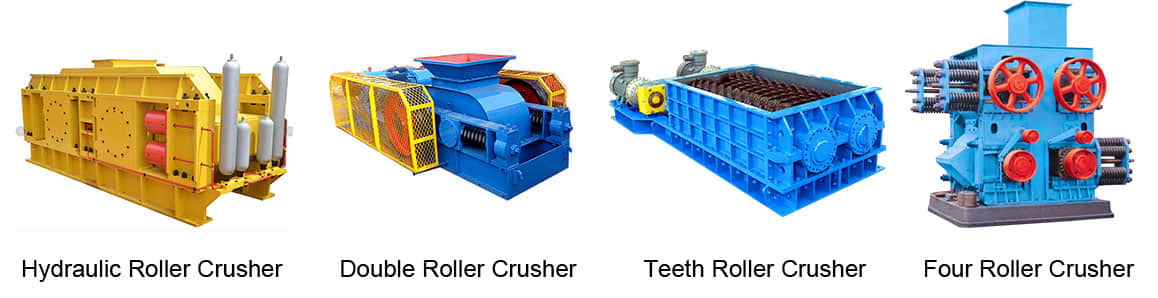

Double roller crusher is widely applied in beneficiation, chemical industry, cement, refractory material, grinding material, construction material and other industrial aspects for crushing various ore and rock with high and middle hardness. Compared with other common crushing machine, Taeda double roller crusher holds better crushing effect.

For roller crusher, materials to be crushed will drop between rollers through feeding port. After extruding and crushing, final product will fall naturally. When encountering hard or unbreakable objects, crusher roller can automatically retreat by relying on hydraulic cylinders or springs so that to make gap between rollers increases and hard or unbreakable objects fall down, which will prevent machine from being damaged. There is a certain gap between rollers rotating in opposite directions. Changing the gap can control discharge size of final product. Double-roll crusher makes use of a pair of oppositely rotating round rollers, while the four-roller crusher uses two pairs of oppositely rotating round rollers to finish crushing work.

Roller crusher relies on high extrusion force produced by opposite rotation of high-strength wear-resistant alloy crushing rollers. After entering gap between rollers, under the action of squeezing, shearing and grinding, materials will be crushed into required particle size and discharged from the discharge port.

Taeda holds 20-year production history and 60-year skllled production team. 95% spare parts are Self-produced and external processing rate for core commponents lower than 3%.

Taeda holds a more than 100-people professional R&D team which can customize one-on-one technical support ba

Various automatic processing devices equipped in production ba

Taeda complete service system covers demand communication, contract signing, equipment delivery, on-site installation guidance and commissioning, which saves customers worries.

| Model | Inlet Size (mm) | Outlet Size (mm) | Output Capacity (t/h) | Motor Power (Kw) | Weight (t) | Overall Dimensions (mm) | |

| 2PG400×250 | <35 | ≤2-8 | 2-10 | 2×5.5 | 1.3 | 2150×980×800 | |

| 2PG400×250 | <35 | ≤2-8 | 2-12 | 2×7.5 | 2.3 | 2360×1100×800 | |

| 2PG400×250 | <65 | ≤2-20 | 5-20 | 2×15 | 3.9 | 3510×1420×1030 | |

| 2PG400×250 | <75 | ≤2-25 | 10-40 | 2×18.5 | 9.5 | 4210×1630×1260 | |

| 2PG400×250 | <80 | ≤2-25 | 12-45 | 2×22 | 10.8 | 4505×1780×1320 | |

| 2PG400×250 | <100 | ≤3-30 | 20-65 | 2×30 | 14.9 | 5310×2175×1595 | |

| 2PG400×250 | <120 | ≤3-35 | 35-80 | 2×37 | 25.5 | 6290×980×800 | |

| 2PG400×250 | <130 | ≤3-45 | 50-120 | 2×75 | 33.7 | 7460×2410×2290 | |

| 2PG400×250 | <150 | ≤3-50 | 30-140 | 2×90 | 41.2 | 8220×2680×2475 | |