Taeda sand dryers also can be called quartz sand drying machine, river sand dryer or sand rotary dryer, is mainly used for drying particle materials with certain humidity, such as all kinds of sand in foundry industry and dry-mixed mortar industry.Clay with small particle size in building materials and cement industry.Small particle size materials with no chemical changes and heat and dust resistance in chemical industry. According to different requirements on moisture content of dried materials in different industries, moisture content of dried materials can be lower than 0.5%.

There are two types sand dryer for customer's choice, single drum and three drum dryer. Cusotmer can choose either one according to real sitaution.

Application

Taeda sand dryer is designed with reasonble structure and adopts superior texture. Therefore, Taeda sand dryer holds better abrasion-resistance ability and longer service life. Except quick wear parts, Taeda sand drying machine can continuously run for many years without multunction.

Whole sand drying system holds very high output capacity, small flow resistance; Whole system can be operated easily and conveniently. After times' upgrading and improvement, energy consumption of Taida dryer is much less than common drying machine;

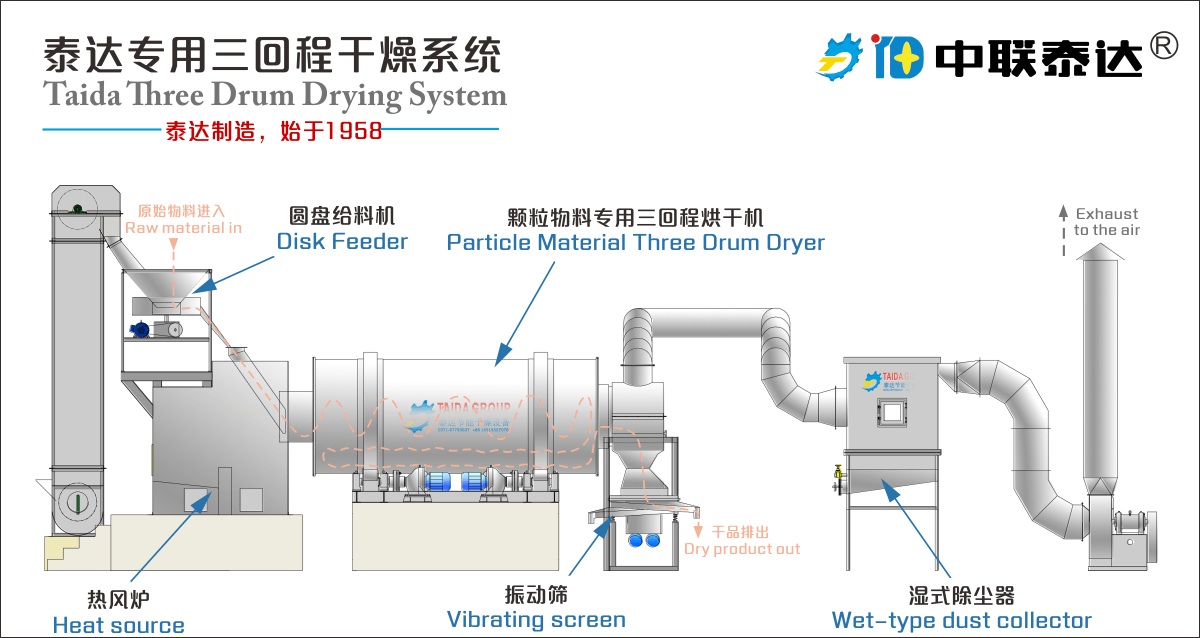

Taeda sand dryer is featured in simple operation, stable running performance, good seal effect and convenient seal performance. It is a ideal drying equipment. Whole system contains rotary drum, lifting plates, support device, seal device, heat source, dust collecting and electrical control. Rational structure and perfect workmanship makes Taeda sand stone dryer durable.

During drying process, Taeda fully considers hardness and moisture features of sand materials so that Taeda ore slag dryer can adapt to various sand materials and used for me

|

Item |

Capacity (t/h) Capacity will be different for different materials. | Power (Kw) | |||

| Silica sand | River sand | Frac sand | Dune sand | ||

| TDLT320.1 | 5~10 | 4 | 4~6 | 10~15 | 11 |

| TDLT320.2 | 10~15 | 6 | 6~8 | 15~20 | 11 |

| TDLT325.1 | 20~25 | 8 | 8~12 | 20~25 | 15 |

| TDLT325.2 | 25~30 | 10 | 12~15 | 25~30 | 15 |

| TDLT328 | 30~35 | 15 | 15~20 | 35~40 | 22 |

| TDLT330.1 | 35~40 | 20 | 20~25 | 40~45 | 30 |

| TDLT330.2 | 40~45 | 25 | 25~30 | 45~50 | 30 |

| TDLT332.1 | 45~50 | 30 | 30~35 | 50~60 | 44 |

| TDLT332.2 | 50~60 | 35~40 | 35~40 | 60~70 | 44 |

| TDLT336 | 60~70 | 40~45 | 40~45 | 70~80 | 60 |

| TDLT338 | 70~80 | 45~50 | 45~50 | 80~90 | 60 |

| TDLT340 | 80~90 | 50~60 | 50~60 | 90~100 | 74 |